Fighting the negative effects of climate change is at the core of our strategy and we recognize the role, relevance and importance of our decarbonization journey.

Like other large-scale industrial activities, the cement industry also produces CO2 emissions, primarily due to the nature of its production process. Most of the emissions occur during a step known as calcination, in which limestone is subjected to high temperatures inside cement kilns to form calcium oxide.

We have implemented different initiatives to align our emission reduction targets with the ambition of the Paris Agreement signed in 2015: to limit global warming to well below 2°C compared to pre-industrial levels, making every possible effort to limit the increase in global temperature to 1.5°C.

In 2022, we approved a new CO2 emission reduction target, in line with the Science Based Target initiative (SBTi). Created by four partner organizations (CDP, United Nations Global

Compact, World Resources Institute and World Wide Fund for Nature), this initiative calls on companies to reduce their greenhouse gas (GHG) emissions, driving the transition toward a low-carbon economy.

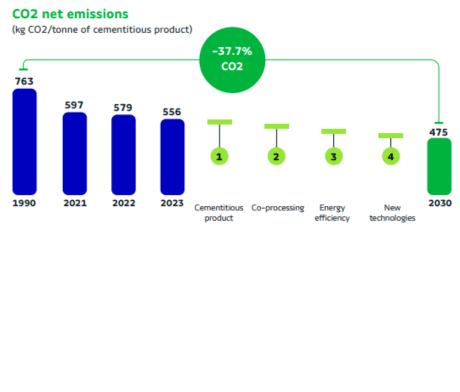

Our new commitment is to limit our net emissions to 475 kg of CO2/tonne of cementitious product by 2030, a target that is 8.7% more aggressive than the previous one (520 kg of CO2/tonne of cementitious product) and represents a 24.8% reduction in our emissions compared to the base year 2018.

Our ambition is to produce carbon-neutral concrete by 2050.

Decarbonization Pillars

To fulfill our new commitment, Votorantim Cimentos’ decarbonization strategy is based on four main pillars:

Co-processing

Substitution of fossil fuels used in cement production kilns for alternative fuels, such as biomass and different types of waste, strengthening the circular economy.

Cementitious products

Substitution of clinker for by-products from other industries, including blast furnace slag and fly ash from thermoelectric plants, in addition to other cementitious materials, such as calcined clay, natural pozzolans and other materials.

Energy efficiency

Optimization of the production process, use of renewable energy sources and investment in the thermal and electric efficiency of our plants.

New technologies

Use of innovative processes and new materials, dematerialization of the value chain, carbon capture, utilization and storage, and partnerships with various entities.

Carbon-neutral Concrete

Concrete has shaped modern society and is vital to humanity. Known for its excellent durability, versatility and resistance, it is considered a sustainable material and has characteristics that make it resistant to fire, temperature changes and flooding. It provides effective thermal insulation in buildings (which reduces energy consumption) and rigidity in road surfaces (which increases vehicle efficiency).

Concrete is the second most consumed resource in the world, after water. Made from cement, concrete is accessible and has numerous applications. It also has unique qualities that enable other sectors, such as the renewable energy market, to develop at the speed necessary for us to achieve, as a society, the target for emissions reduction set by the Paris Agreement.

In a world that is rapidly urbanizing—according to UN Habitat, 68% of the world’s population will be living in cities by 2050— concrete is considered the best material to meet the need for housing and infrastructure.

As part of our search for more sustainable solutions to produce, commercialize and use our products in different applications, we were one of the founders of the Global Cement and Concrete Association (GCCA) and, together with other companies in the industry, we work tirelessly toward our goals. In 2021, we joined forces with the world’s leading cement and concrete producers to accelerate the shift toward greener concrete by committing to produce carbon-neutral concrete by 2050.

Carbon-neutral Concrete

Concrete has shaped modern society and is vital to humanity. Known for its excellent durability, versatility and resistance, it is considered a sustainable material and has characteristics that make it resistant to fire, temperature changes and flooding. It provides effective thermal insulation in buildings (which reduces energy consumption) and rigidity in road surfaces (which increases vehicle efficiency).

Concrete is the second most consumed resource in the world, after water. Made from cement, concrete is accessible and has numerous applications. It also has unique qualities that enable other sectors, such as the renewable energy market, to develop at the speed necessary for us to achieve, as a society, the target for emissions reduction set by the Paris Agreement.

In a world that is rapidly urbanizing—according to UN Habitat, 68% of the world’s population will be living in cities by 2050— concrete is considered the best material to meet the need for housing and infrastructure.

As part of our search for more sustainable solutions to produce, commercialize and use our products in different applications, we were one of the founders of the Global Cement and Concrete Association (GCCA) and, together with other companies in the industry, we work tirelessly toward our goals. In 2021, we joined forces with the world’s leading cement and concrete producers to accelerate the shift toward greener concrete by committing to produce carbon-neutral concrete by 2050.